Flash memory is a non-volatile, programmable, high-speed chip-based storage technology that retains data even without a constant power supply. There are two types of flash, NAND and NOR, each with different strengths and weaknesses which makes it better-suited to different uses.

NOR flash memory is typically used in cell phones, Internet of Things (IoT) devices, medical devices, and scientific instruments, while NAND is used in digital cameras, USB drives, Secure Digital (SD) memory cards, tablets, and computers. In some cases, digital devices like computers and cell phones use both NAND and NOR—for example, NAND flash in the solid state hard drive (SSD) and NOR flash in the operating system BIOS.

This article provides a high-level overview of both types of flash memory and what sets them apart.

What is NAND?

Flash memory stores data in memory cell arrays defined by Floating Gate Metal Oxide Field Effect Transistors, which store a binary 1 or 0. Each transistor has two gates, like an electrical switch where the current flows between two points. The name NAND stands for NOT-AND, the type of logic gate it uses.

Unlike DRAM memory, it does not require a persistent power source. When the SSD or memory card is detached from a power source, metal-oxide semiconductors called floating-gate transistors (FGT) provide electrical charges to the memory cells and data remains intact.

NAND is the most popular type of flash storage memory for USB flash drives, memory cards, and solid state drives (SSDs). NAND cell arrays store between one and four bits of data.

Types of NAND

The most common types of NAND are SLC, MLC, and TLC, which contain between one and three bits in each cell. 3D NAND, which stacks cells vertically, is also gaining ground in high-performance, high density environments.

- SLC: Single-Level Cell NAND stores one bit of information per cell. The architecture delivers the highest endurance, performance, and data integrity of the bunch with an endurance rate of 100,000 program/erase (P/Es) cycles, which is the number of times a cell can be erased and rewritten into. SLC NAND is the most expensive flash memory on the market today and is used in industrial applications that require endurance and speed.

- MLC: Multi-Level Cell NAND stores two bits of information per cell. This lowers the price per capacity over SLC, but makes it more susceptible to data errors with a lower endurance rate. MLC chips are generally found in consumer products such as laptops and PCs due to their affordable price and performance.

- eMLC: Derived from MLC, Enterprise Multi-Level Cell still stores two bits per cell but is enhanced for commercial use. eMLC drives are more expensive than MLC but less expensive than SLC, and have an intelligent controller that manages wear leveling and data placement to help extend useful life.

- TLC: Triple-Level Cell NAND stores three bits per cell, reducing cost and endurance and increasing capacity. WIth an endurance rate of just 3,000 P/E cycles, it is the least expensive type and is primarily used in consumer products.

- QLC: Quad-Level Cell NAND stores four bits per cell, creating higher density and high-capacity storage devices. QLC’s lower read latency suits read-intensive operations with applications such as Artificial Intelligence (AI), machine learning, Big Data, and content delivery. Though QLC is excellent for read operations, its endurance is just 1,000 P/E cycles, making it unsuitable for write-heavy applications. But the low power consumption helps improve the battery life of devices.

- 3D NAND: Flash manufacturers are on a mission to decrease cell sizes to pack more transistors on microchips that increase the capacity of a NAND device. However, shrinking cells using the above cell-level technologies resulted in cell-to-cell interference, which reduced data integrity in NAND flash. Multilayered flash increases capacity and keeps costs low by vertically stacking memory cells in multiple layers. With the move from two dimensions to three, 3D NAND devices achieve higher density and lower power consumption, faster reads and writes, and increased endurance. In addition, vendors use silicon nitride film known as charge trap flash when vertically stacking memory cells to reduce manufacturing cost, decrease chip size, and improve reliability. The charge trap flash replaces the floating gate technology, which helps reduce overall manufacturing costs.

What is NOR Flash?

NOR flash was the first type of flash developed. Cells on a NOR chip are arranged parallel to one another, making it efficient to read but not as fast for writes. It is most often used in cases where code will be written once and read a lot.

It can be manufactured in small chips, and is solid state, which makes it shock-proof and suitable for use in devices that might be moved around or dropped. The name stands for NOT-OR, the type of logic gate it uses.

There are two main types of NOR flash memory, parallel and serial. With parallel NOR, a memory controller uses an eight-bit or 16-bit parallel address bus to address the memory. Serial NOR, or Serial Peripheral Interface (SPI) NOR, stores data in both pages and larger sectors.

NAND vs. NOR

Both NOR and NAND flash memory are embedded in small electronics like cameras and smartphones, but only NAND is cost-effective and dense enough to serve in flash-based enterprise storage environments. Neither technology is new, having been developed by Toshiba in the early 1980s.

- Deployment. NAND is used far more than NOR flash memory. One of the most advanced 3D NAND microchips released this year by Kioxia and Western Digital is a 218-Layer 3D NAND chip with a record-breaking 3200 MT/s interface speed, an effective rate of 25,600 MB/s. It is faster and better suited for long-term storage, which is commonly used by business-critical enterprise applications.

- Memory cell connections. NOR flash connects each memory cell to the source line and the other end to a bit line, which allows multiple cells to simultaneously connect to a bit line. Since the cells are connected in parallel, the system can write and read to individual memory cells. NOR flash works best when using small data sizes, similar to an operating system BIOS code that controls a computer’s initial boot-up sequence and hardware initialization. Alternately, NAND cells are connected in a series that takes less space and does not allow writes to individual memory cells. These serial connections take less room, but do not allow direct writes to individual memory cells.

- Read performance. NOR flash reads faster than NAND flash. When comparing a NAND MLC flash device against a NOR MLC device, the NAND device read rate is about 20.5 MBps, while the NOR device read rate is 61.5 MBps. This is because NOR allows random access to any memory address. NOR flash memory allows the system to read bytes independently of pages and blocks. NAND reads are slower since it supports page and block access, not random access. NAND reads data in blocks, with typical block sizes of hundreds and thousands of bits.

- Write and erasure performance. Conversely to read performance, NAND microchip writes and erases are faster than NOR devices.

- Endurance. NOR flash memory has byte-level writing that helps improve its endurance compared to NAND memory. NAND must erase in blocks (i.e., 512 data bytes) even when only a single byte has been changed. NOR cells have 100 percent known good blocks over the cell’s life, while NAND cells typically have 98 percent good bits when shipped—NAND manufacturers usually add error correcting code (ECC), which NOR does not need.

- Density. NOR memory has less density than an equivalent NAND flash memory chip. NOR densities range from 64MB to 2GBs, while NAND ranges have expanded to 2TBs with the Micron 232-Layer NAND chip.

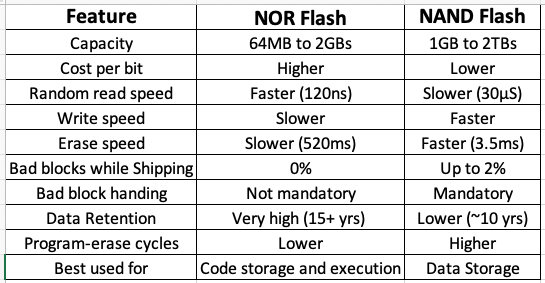

NOR and NAND Comparison Chart

Bottom Line: NAND vs. NOR Flash Memory

Though NAND memory continues to be the most popular type of flash memory, NOR flash memory is still valid when used in the right technological situation. Both have a place in modern devices, with significant improvements to each occurring on a roughly two-year cycle. As of mid-2023, an overabundance has driven the price of NAND microchips down significantly. In turn, the cost of SSDs using NAND flash has dropped as well, making faster, higher capacity storage more readily affordable. NOR pricing has followed a similar trend, making it a good time for businesses looking to purchase solutions built upon these technologies to act.