3-D NAND is the most advanced form of NAND, enabling greater speed, lower cast and higher density than earlier versions of NAND.

First, let’s take a quick glance back. NAND is non-volatile flash memory storage that does not need power to retain data. NAND storage appears in a wide range of products, from small consumer devices to high-capacity SSDs in flash-based enterprise data centers.

However, 2D NAND – also called planar NAND – has reached the limits of its capacity development. 2D NAND capacity growth is constrained by how many memory cells can fit within finite width and length dimensions.

Although manufacturers attempted to grow NAND capacity by shrinking cell sizes, the experiments did not deliver. Problems occurred due to cell sizes and electrons. 2D NAND cells must have enough space to store sufficient electrons. If there are too few electrons because the cell is too small, then cell functioning decreases and cell-to-cell interference increases. Performance, endurance, and reliability all suffer.

This is where 3-D NAND comes in.

What is 3D NAND?

3D NAND, also called Samsung V-NAND, was developed to overcome 2D NAND’s capacity limitations. 3D NAND architecture scales to higher densities without sacrificing data integrity.

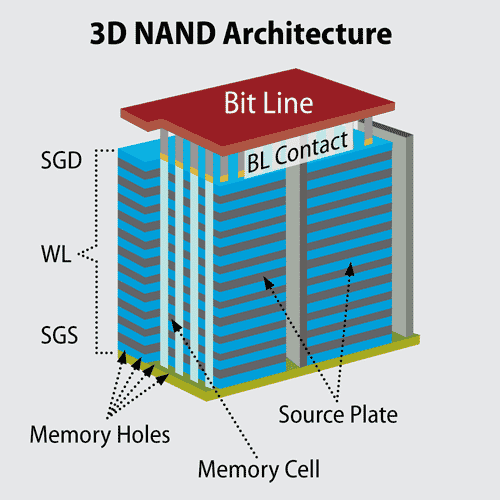

Unlike planar NAND where memory cells are stacked horizontally on cards, 3D NAND is stacked vertically using multiple layers to achieve higher density, lower power consumption, better endurance, and faster reads/writes, and a lower cost per gigabyte. Because it packs so many vertical cells into small width and length dimensions, 3D NAND has far more capacity than 2D NAND within the same length and width dimensions.

3D NAND uses advanced architecture to provide high performance in a flash environment.

Use Cases for 3D NAND

- Hyperconverged infrastructure (HCI). HCI is useful for the large complex data center, but can also be very expensive. 3D NAND increases capacity at flash speeds and at lower cost, which allows HCI users to increase performance and scale at reasonable prices.

- High-capacity environments. 15TB and above 3D NAND SSDs are in the market today, and 2U units with up to 6PB of storage are in development. These capacities are expensive, because they require not only sheer capacity but intelligent controllers and fast performance. However, the price of gaining 128TB and above with high performance and low latency is an attractive proposition to large data centers.

What are the NAND Types in 2D and 3D?

NAND comes in different bit counts per cell, which impacts performance and durability. NAND cells contain 1,2, 3, or 4 bits: SLC, MLC, TLC, and QLC. 3D NAND also comes in MLC, TLC, and QLC, but not SLC. For more background, you may want to compare SLC vs. MLC vs. TLC.

- SLC. Single-Level Cell stores 1 bit in each cell. This design delivers the highest endurance and speed among the four types. It is also the most expensive. 3D NAND does not come in this type.

- MLC. Multi-Level Cell stores 2 bits per cell, which lowers price-per-capacity with somewhat lower endurance. eMLC is MLC with a more power controller that better manages wear leveling and data management. Both 2D and 3D NAND come in MLC.

- TLC. Triple-Level Cell stores 3 bits per cell. It was the lowest performing type, but 3D NAND architecture and better controllers have improved TLC for read-heavy enterprise applications.

- QLC. Quad-Level Cells store 4 bits per cell, and is more common in 3D NAND than 2D NAND. Its structure results in lower endurance is lower than the other types, although better controllers are raising P/E rates. QLC comes in a 3D NAND architecture.

3D NAND Pros and Cons

Pros:

- Higher capacity in a smaller space compared to 2D NAND. 3D NAND SSDs can pack in over 1 TB in a 2.5” form factor, and development continues. Samsung for example makes a 30 TB SSD and is developing much higher capacities.

- Lower cost per gigabyte. 64 layers and above yields meaningful cost reductions over 2D NAND. The difference lies in how many TBs the NAND can store per wafer (the silicon base for the embedded chip). In 2017, 2D NAND could store 1.6 TB, while 3D NAND could store 17.2 TB. Although 3D NAND wafers nearly doubled the cost of planar NAND wafers, 3D NAND’s big increase in capacity still dropped the price-per-GB.

- Higher performance with less power consumption. 1-pass 3D NAND programming enables higher speed read/write bandwidth and IO. This results in a lower power draw than 2D NAND: 3D NAND consumes up to 50% less power than planar NAND.

Cons:

- Contamination control. Manufacturers continually try to increase the amount of memory cells in a stack. But there is an issue: 3D NAND cells are built vertically as strings, so a defect in a single cell can affect the performance of a cell string. Protecting against contamination requires strict manufacturing controls and higher material purity.

- Complex ECC and flash management. 3D NAND needs advanced data management and error correction from its controllers to increase P/E cycles.

- Competitors. 3D NAND is not the only high-capacity flash memory product in the market. Technologies like 3D XPoint (pronounced “3D cross point”) is in the market now, and RRAM (resistive random access memory), SSS (solid state storage), and PCM (phase change memory) are all under development.

3D NAND Flash Memory Market

Research and Markets “Global NAND Flash Market 2018-2020” report projects the global NAND market to grow at a CAG of 15.13% from 2018 to 2022. The projection includes both planar and 3D NAND, and states that 3D NAND adoption is a key growth driver in the market growth.

However, there are pricing pressures on 3D NAND.

- Manufacture is complex and expensive. Stacking and connecting 3D NAND layers takes more process steps than 2D NAND does, making manufacturing more expensive. And since 3D NAND requires purer materials, fabrication costs are 3 times more expensive than planar NAND. In 2017, Micron reported that the cost of NAND flash bit production had doubled from $9 billion in 2015 to $22 billion. The reason was retooling factories and buying purer materials for 3D NAND production.

- 3D NAND needs more silicon. 3D NAND chips have multiple layers, which increases the cost of silicon per chip. They also require purer materials than 2D, and silicon has technical limitations around scaling performance. R&D is experimenting with new materials, and some compound semiconductors are already in the market. However, it’s a long road between experimental materials and at-scale flash memory manufacture.

- Oversupply. Although NAND had issues in 2017 with shortages and supply chain issues, coming into 2019 the problem is 3D NAND oversupply. Product manufacture for the current technology generation is more efficient than it was, and factories are producing more to meet demand. However, demand is falling, and prices are falling with it. Gartner reported that average prices will fall 23% in 2019, following a price drop in 2018.

- Technology transition. 3D NAND may be less expensive per GB than NAND, but that is only the purchase price. Converting from a 2D NAND environment to 3D NAND is 3-5 times more expensive than replacing a 2D NAND with a new 2D NAND node.

3D NAND vs. Planar NAND

Given these challenges, is 3D NAND still better than planar NAND?

The broad answer is yes. 3D NAND is a proven, cost-effective technology that is in the market now. It offers better energy efficiency, higher performance read/write and I/O, and much higher capacity than 2D NAND at lower cost per GB.

Adopting 3D NAND takes some investment in retooling storage infrastructure and transitioning storage. But this temporary pain is worth the benefits for high data growth/high performance environments.